Interstate Conex LLC is an authorized sales affiliate for 360 Products North America venting systems

Container Ventilation EVOLVED!

We Prevent "Container Rain"

On – Grid or Off – Grid. Introducing new patented technology that is so effective, it can eliminate condensation and excessive heat buildup in a Conex/Storage container using only outside air movement to “drive” the needed 24/7 airflow!

Don’t just take our word for it—Scott M. with La Mesa-Spring Valley School District shares how these vents have changed the way they operate for 15 months and counting! Read More >>

use discount code: corry

How Does it work?

Why Us?

First We provide a 10% discount over the factory direct pricing!

Second, What makes us your best choice for shipping container/conex venting solutions? We invented, manufacture, and market our own patented “flow through” technology to address the complex venting challenges of re-purposing a seagoing shipping container (conex) into a reliable storage facility.

Solution to an old problem

No need to spend any more time figuring out how to prevent “container rain” or deal with excessive heat build-up using those old and ineffective “DIY” projects. Our game-changing “Tunnel Series” technology requires no moving parts to wear out, needs no maintenance, has built-in screens and weather protection, and works 24/7/365 using nothing more than outside air currents for a power source. And best of all, our vents are made to fit your container walls with no welding, screws, mechanical fasteners or modifications needed!

use discount code: corry

Innovation

Our revolutionary “Tunnel Series” design is the only system on the planet that uses no moving parts and does not require an outside power source to provide a truly continuous air flow through your shipping container/conex. Perfect for “Off-Grid” applications where electrical power is not available or desired.

Continue exploring our website to learn how we can give you the best protection available regardless of your climate conditions.

use discount code: corry

Does this application work for you? Talk to a real person!

Yes, it really works. Here’s why—

We already know that traditional louvered venting cannot create the “drive” necessary for air exchanges and is not an effective solution when you need constant airflow. Our new technology now makes that possible. Explore for yourself!

Must See Video

Easiest Ever Installation Instructions

How and Why it Works!

Installation

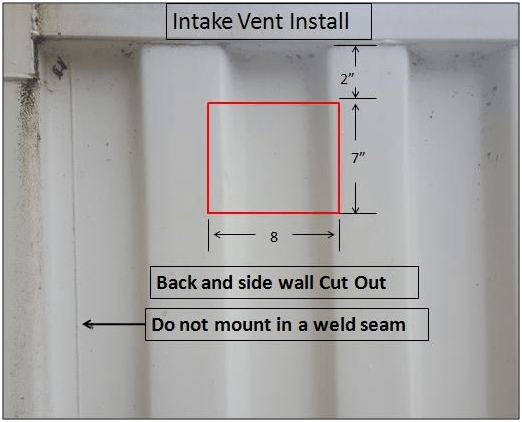

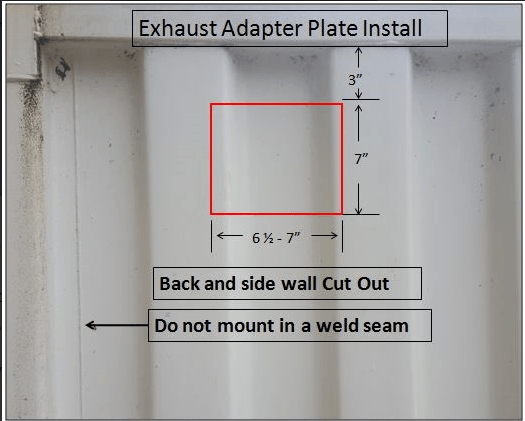

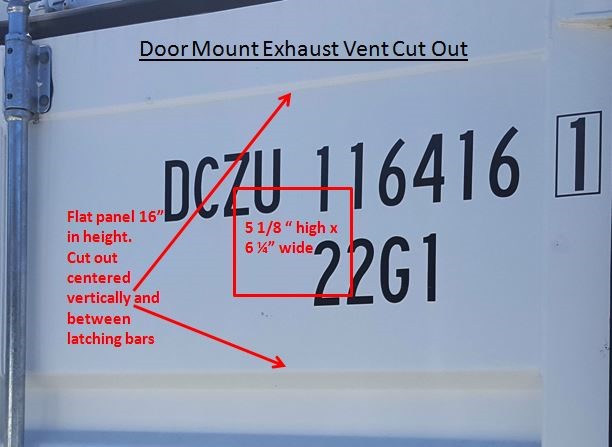

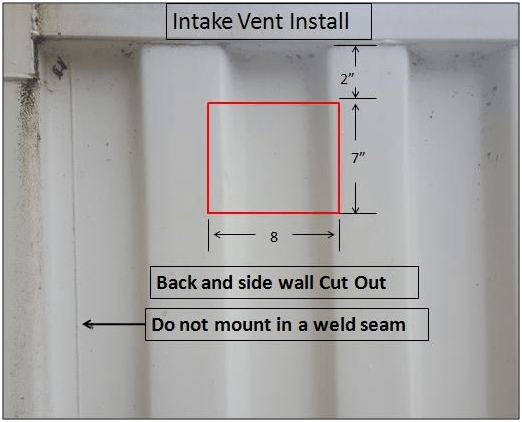

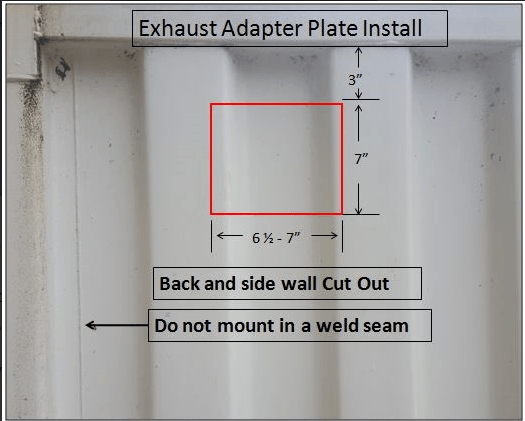

Once the vent locations are determined, mark the port openings as per the cut-out instructions for both the Exhaust and the Intake, as below.

Typical Exhaust vent location

Typical Intake Vent location

Alternate exhaust Vent location

Adapter plate required

2. Cut the rectangle holes, clean off filings

3. Prep the mounting surfaces with the abrasive sanding block now provided. Clean thoroughly and apply rubbing alcohol (IPA) diluted by 50% water. Dry with a clean rag.

4. Remove the red protective cover from the tape backings on the vents, and press the vents in place

The parts needed

Not always needed, contact us for details

5. Press well to make sure initial contact is made. Cure is secure at 40% (after 20 minutes). The “Exhaust Driver” has two parts, port then cover. Intake has one part. The 3M tape takes about 24 hours to cure completely.

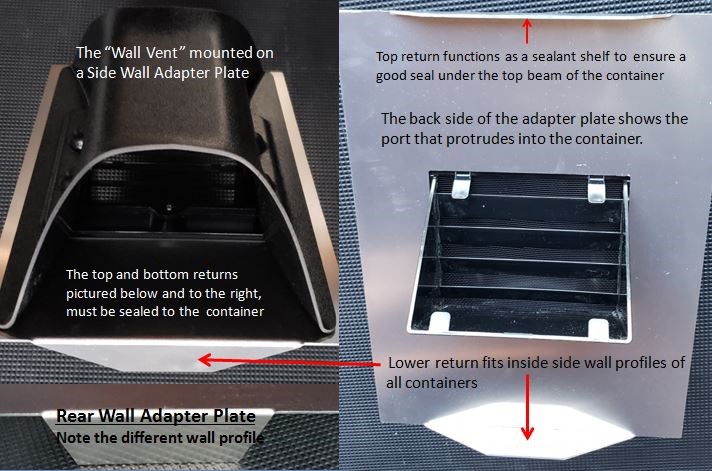

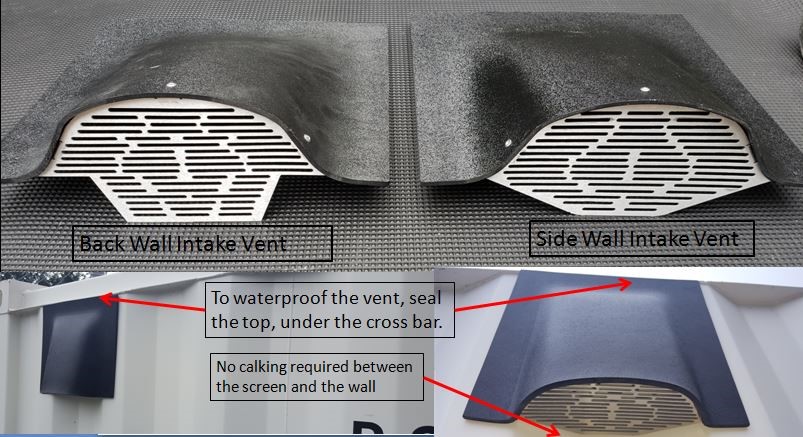

6. The 3M brand commercial grade tape has outstanding adhesion properties and provides an excellent weather seal. To compensate for container imperfections, an exterior sealant is still required for the top of the intake and the top and bottom of the adapter plates (if required). For the extra minute it takes, we suggest applying a bead of sealant around the outer edges of all the vents and parts.

Our team can reach back out to you to help!

You are done…Simple as that!

Note: There are literally hundreds of sealants in small, individual tubes available at all Hardware/Home Improvement stores across the country. We recommend asking their sales associates which ones they would recommend for a small, one time application such as ours.

Planning My Container Vent Locations

Vent Options: The goal is to maximize the conditions of the container location, it’s size and how it’s positioned regarding wind direction, wind obstacles and sun / shade. To allow for these variables we have products specifically designed to fit the contours of different walls. The “Wall Exhaust” pictured will automatically fit the flush surface of the doors but can also be installed on side or end walls using the appropriate adapter plate. “Intake” vents are automatically contoured to fit the individual side and end wall corrugation.

See “Vent Placement” for designing the optimum ventilation system.

Considerations

use discount code: corry

Intake

Regardless how many of the small stock rectangular vents (See “Stock Vents and Comparisons”) are presently on the walls, a proper intake will be required at the opposite end of the Exhaust. This will allow air to be pulled by the exhaust driver throughout the entire container. One intake can feed 2 Exhaust vents. If possible mount the intake on the shady side. Side walls are a different profile than rear walls, note the screen shapes provided here.

Determine Vent Quantity

A 40 foot container needs more ventilation than a 20 footer. The formula works based on how many air exchanges can be completed each day. See “Low Winds and Air Exchange Tables”.

Please Note

Keeping a large metal box condensation free without power is not always simple as some locations are tougher than others. For the best success with our product, download our free guide, “8 Steps to a Dry Container,” and implement whatever is possible.

We want success for all our customers, so please review all the links listed above to ensure all the variables have been considered when designing your ventilation system and call us if you have questions.

Testimonials

School District's Mildew Problem Solved

“I installed your 360 container vent system back in Sept 2019. I am reviewing this product a year and five months later. I used two intakes and two exhaust per 40 foot container as suggested. We had a terrible problem with container rain and mildew build up. After we installed this system we cleaned all the mildew off the ceiling of four different containers and have not had a problem since. These vents work! Thanks Bob for your help in deciding to purchase this product.”

Scott M.

La Mesa-Spring Valley School District

Contact Us

Copyright 2018 INTERSTATE CONEX LLC